Operations

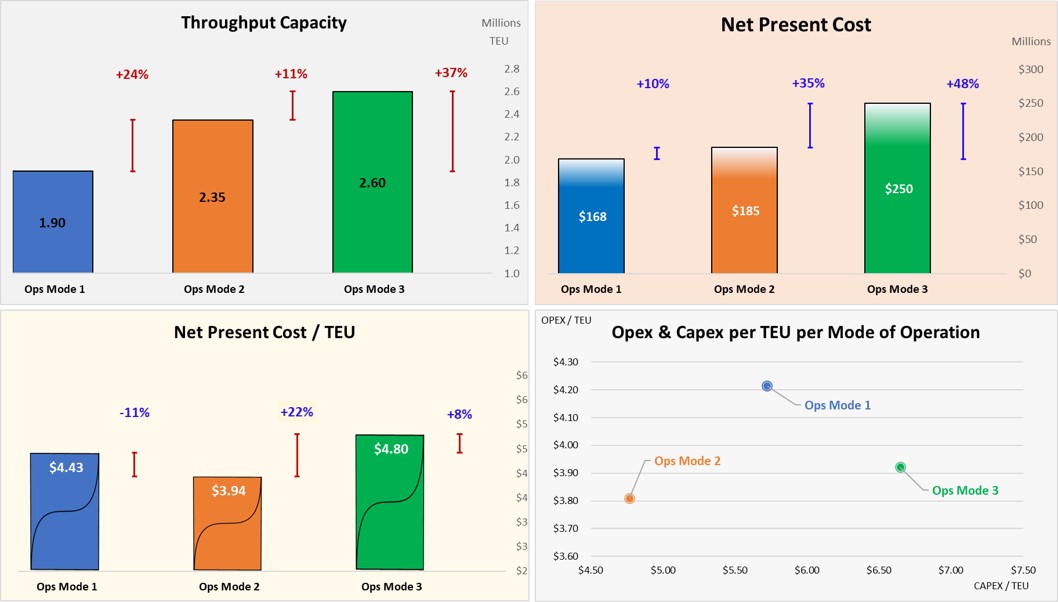

Optimal Operational Mode Analysis

In order to select the optimal operational mode that offers the best compromise between the various requirements and constraints such as Throughput capacity, Real-estate, Capex and Opex ... a feasibility study of several mode of operations is carried out and the results are benchmarked side by side to return the NPC/TEU, Capex/TEU; Opex/TEU, TEU/Hectares and TEU/quay meter. allowing the Terminal management to make an informed decision.

Detailed Capacity & Throughput Analysis (Supply & Demand)

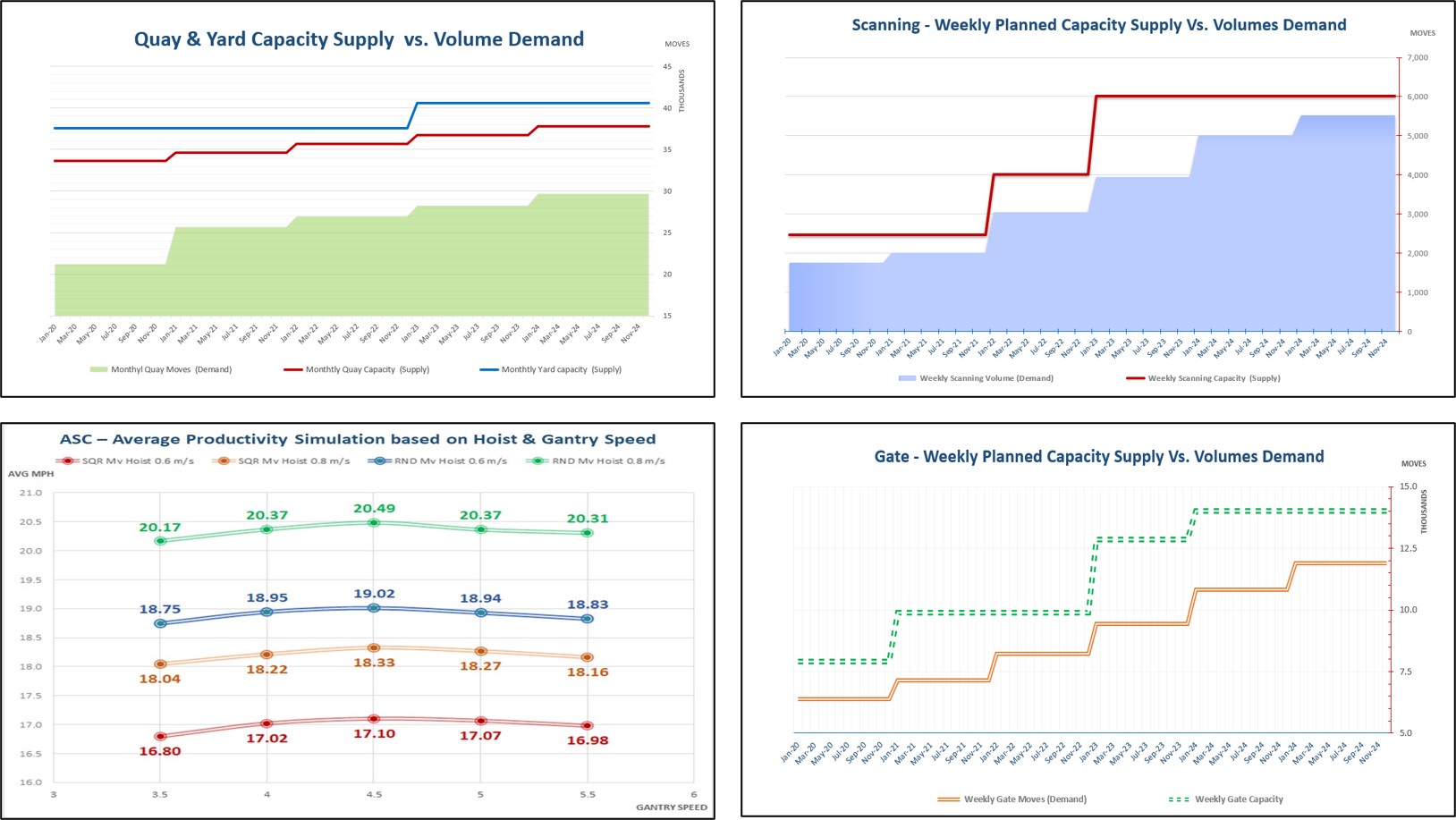

The Terminal supply & demand analysis also known as Operational Capacity Modelling consist of a mathematical analysis per module of operations at the initial stage and later as full end to end terminal operations stock and flows capabilities.

The operational modules follow the natural cargo flow in the terminal, starting by the Waterside operation, followed by Yard, Gate and Rail operation; Identifying at each stage the throughput Capacity, the Occupancy as well as the handling equipment requirements.

Other Operational calculations are done to identify the Equip running Hours, Energy consumption and Emission Calculation.

Sensitivity Analysis

After the Mathematical analysis, a sensitivity analysis is undertaken in complex cases where a higher degree of certainty is required. this sensitivity analysis allows to test different scenarios and business assumptions and validate the selected operational concept.

TCO Calculation

TCO (Total Cost of Ownership) is a calculation method that determines the overall cost of the equipment throughout its life cycle.

OEE Analysis

OEE (Overall Equipment Effectiveness) is the standard for measuring equipment productivity. Simply put – it identifies the percentage of time that is truly productive.

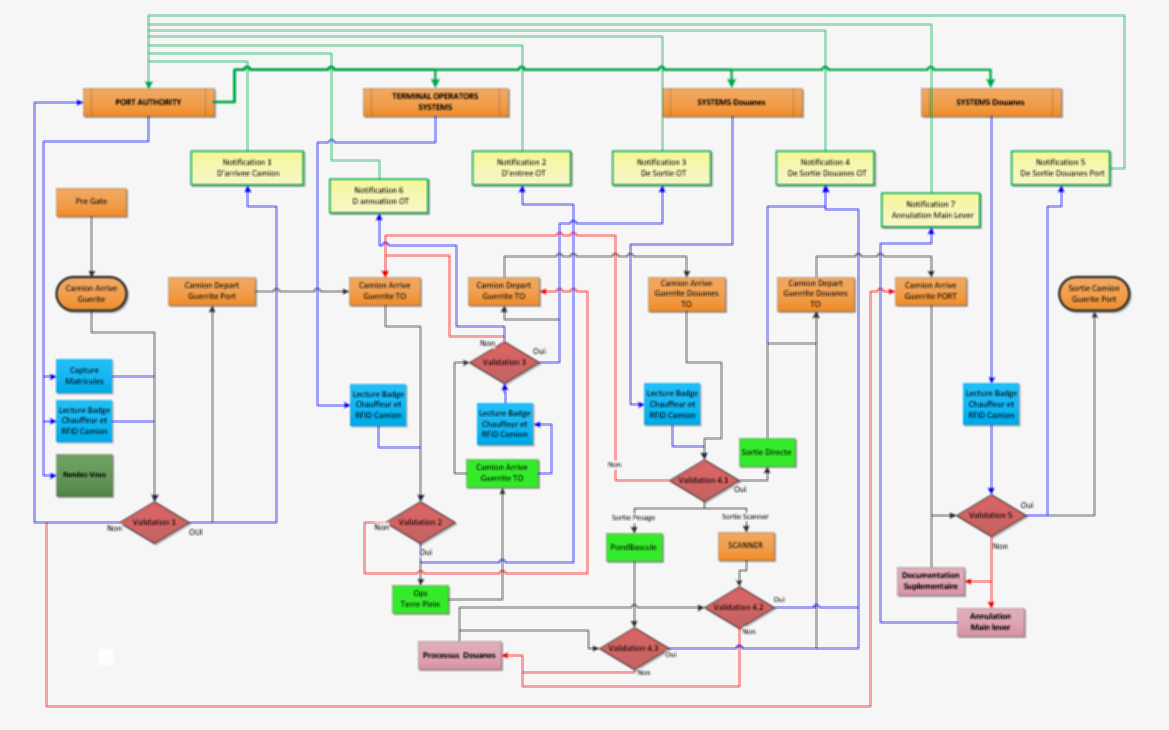

Process Mapping and Improvement

Based on a strong ports operations expertise and experience, we provide process improvement skills and competencies to Container Terminal operations to enhance the efficiency and effectiveness of terminal operations.